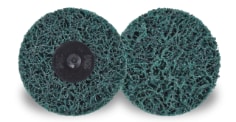

Scotch-Brite™ Roloc™ Clean and Strip XT Pro Extra Cut Disc XC-DR, 76 mm, A XCRS, Green

- 3M ID 61500303369

- UPC 50638060215451

Details

Highlights

- Quickly removes heavy rust, thick paint, corrosion and cleans welds

- Aluminium oxide mineral aggressively removes top layer and refines the bare metal underneath

- High conformability provides a larger contact patch for faster removal rates

- High-strength fibre resists chunking and performs well on edges

- Resists loading for consistent cutting action

- High speed rating and low vibration

- Roloc™ attachment system makes disc changes easy

- Requires use of Roloc™ backup pad (sold separately)

Scotch-Brite™ Roloc™ Clean and Strip XT Pro Extra Cut Disc features aluminium oxide abrasive mineral incorporated into an open nylon web. Our discs are designed to remove tough coatings, such as heavy rust, thick paint and corrosion, while also blending and refining the bare metal underneath.

Get increased conformability without compromising on strength when preparing metal surfaces, or removing rust and paint, with Scotch-Brite™ Roloc™ Clean and Strip XT Pro Extra Cut Disc. Our discs feature a combination of reengineered fibre strands, resin and aluminium oxide mineral abrasive to form a thick, open web. The spring-like nature of the fibres means our discs are able to follow the contours of the workpiece with greater accuracy, achieving a larger contact area for faster removal rates. They conform to weld bead ripples to polish welds and allow you to work in hard-to-reach areas. Aluminium oxide is a very hard mineral that delivers a high cut rate. Commonly used in high-pressure applications like cutting and weld removal, it cuts aggressively removing heavy rust, thick paint and corrosion without leaving divots, simultaneously preparing the base material underneath. This means that operators can remove a coating from a workpiece and get it ready for welding or adhesive application with the same disc – saving the time of switching abrasives. Furthermore, gaps in the web allow swarf to escape, minimising loading of the abrasive. To ensure a consistent cut over the life of the abrasive, the disc’s strengthening resin bond gradually breaks down through use to reveal new fibres and super-sharp aluminium oxide abrasive. The high-strength fibre resists chunking and provides low vibration, a high-speed rating and a long service life. These discs come with the added benefit of a Roloc™ attachment. Operators can quickly attach the disc to a Roloc™ backup pad (sold separately) that connects to the power tool, minimising set up and connection times, and helping to enhance productivity.

Typical Properties

Resources

Connect with us. We’re here to help.

Send Us a Message

Thank you for your interest in 3M. In order to help us manage and respond to your query effectively, we politely ask you to provide some key information, including your contact details. The information you provide will be used to respond to your request through email or telephone by a 3M representative or one of our authorised business partners with whom we might share your personal information consistent with the 3M privacy policy

Thank you for your contacting 3M

We have received your message and are now looking into your enquiry

One of our representatives will get in touch with you by phone or email

Scotch-Brite™ Roloc™ Clean and Strip XT Pro Extra Cut Disc XC-DR, 76 mm, A XCRS, Green

Scotch-Brite™ Roloc™ Clean and Strip XT Pro Extra Cut Disc XC-DR, 76 mm, A XCRS, Green Scotch-Brite™ Clean and Strip XT Pro Extra Cut Disc

Scotch-Brite™ Clean and Strip XT Pro Extra Cut Disc